High Purity Calcium Hydroxide Ca(OH)2 is used in the process of making biodiesel from used cooking oil to neutralize free fatty acids. This stage is called trans-esterification, where triglycerides in free fatty acids are reacted with alcohol (usually methanol) to produce methyl esters (biodiesel) and water.

However, if the free fatty acid content is too high. The trans-esterification reaction (the main stage of biodiesel production) will not run optimally. Therefore, it is used to reduce the free fatty acid content through a neutralization reaction, so High Purity Calcium Hydroxide Ca(OH)₂ here functions as a reaction catalyst because Calcium Hydroxide is a strong base, insoluble in methanol, and easily separated after the reaction.

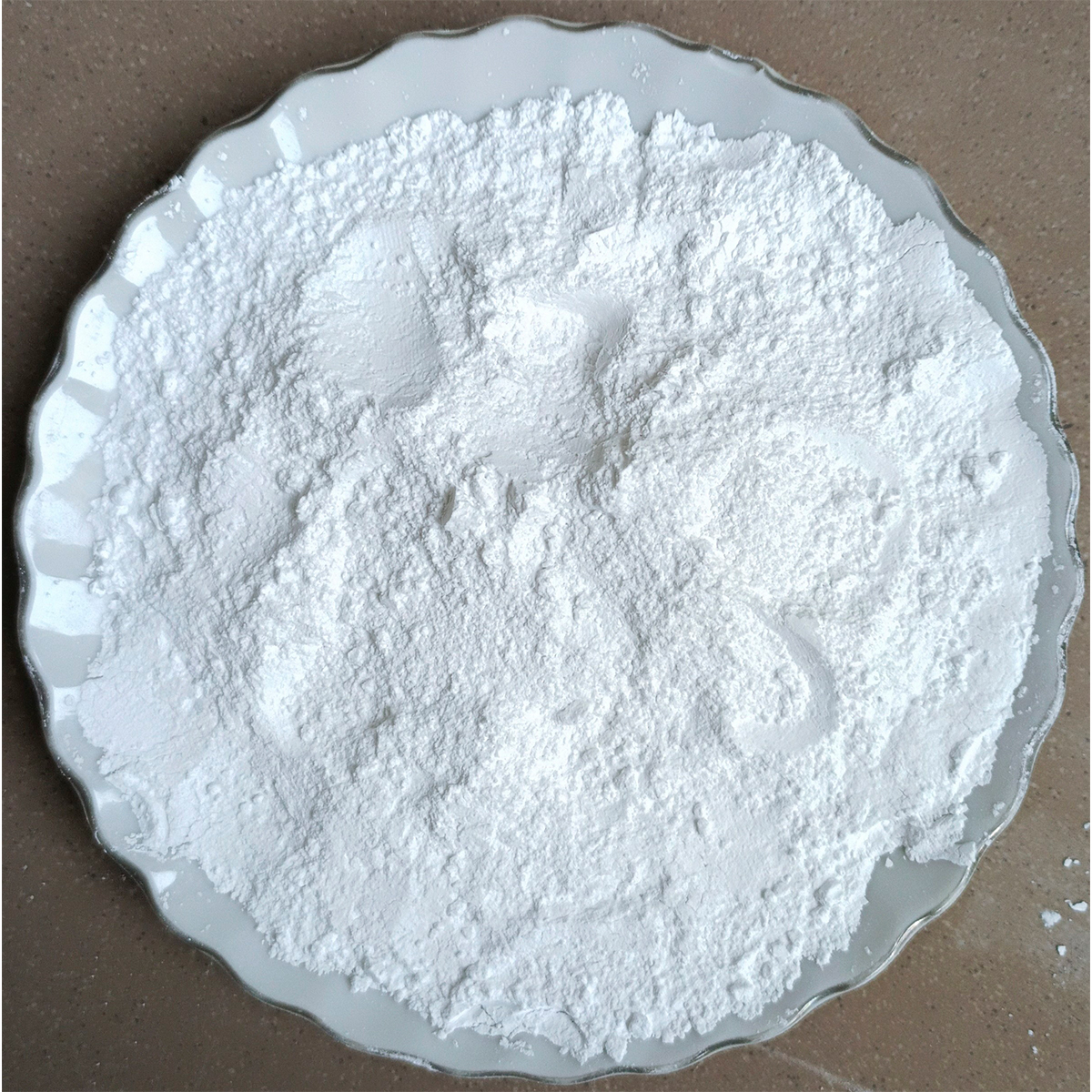

high purity calcium hydroxide is used in the process of making biodiesel from used cooking oil

First, the process begins by mixing calcium hydroxide into the heated used cooking oil. Subsequently, high-purity calcium hydroxide will react with free fatty acids to form calcium soap and water (H₂O).

This calcium soap is then separated from the oil mechanically through a centrifugal filtration or sedimentation process. After the free fatty acid levels are reduced, the used cooking oil is ready to go through the trans-esterification stage, where the oil is reacted with methanol and a Calcium Hydroxide catalyst to produce biodiesel.

After the transesterification reaction is complete, the biodiesel mixture still contains impurities such as soap, glycerol, and solid particles. Calcium hydroxide can be reused in the purification stage to help purify biodiesel.

Purification Process: The biodiesel mixture is washed with water to remove residual acid, soap, and glycerol. High Purity Calcium hydroxide can be added to the wash water to neutralize residual acid. This helps stabilize the pH and ensures that the biodiesel produced meets quality standards. In addition, it can also act as an adsorbent to bind fine particles remaining in the biodiesel; as a result, this is useful for increasing purity.

PT. Niraku Jaya Abadi Products for Food Processing Applications, CLICK HERE

📞 CALL US: 0878 5868 7898

📧 Email: sales@niraku.co.id

🌐 Website: http://niraku.co.id/